According to the news from The Korean Herald, Samsung has signed a contract with Apple about supplying 100 million OLED glass lens in 2017. Another news revealing that LG has also added a product line for OLED screen, which will be put into production in early 2017. So in early 2017 or at the latest by 2018, we will see iPhone made of OLED screen.

As for the influences to the mobile phone repair industry, let’s first take a look at the supply of the mobile phone repair parts market.

Take the most popular iPhone replacement screens for example, there’re 4 different types of sources;

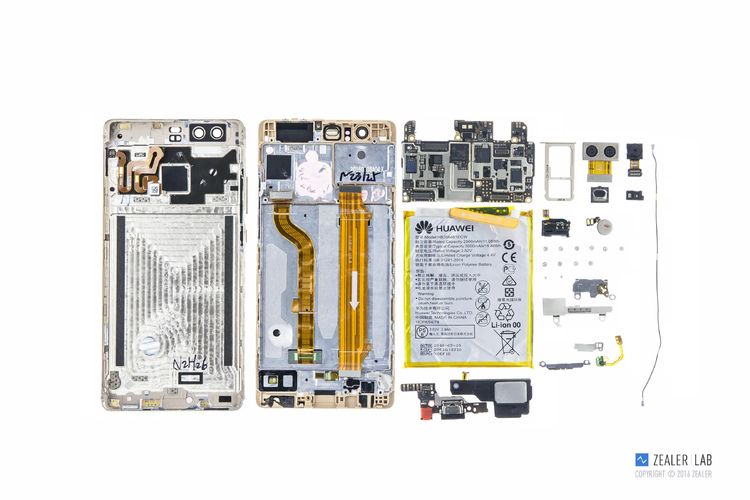

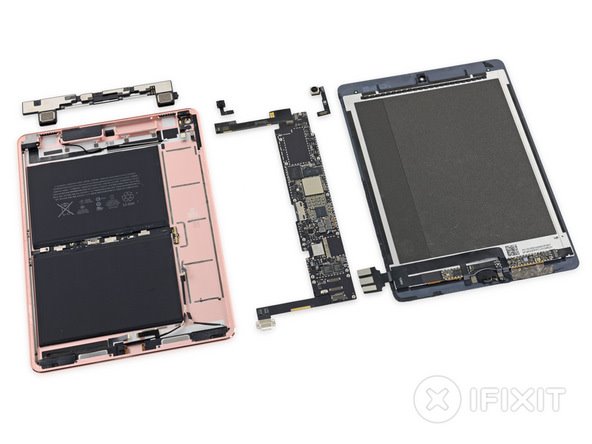

1. The original replacement screen

The main sources for original LCD screen replacements are spare inventories from original manufacturers or defective parts from original assembly lines.

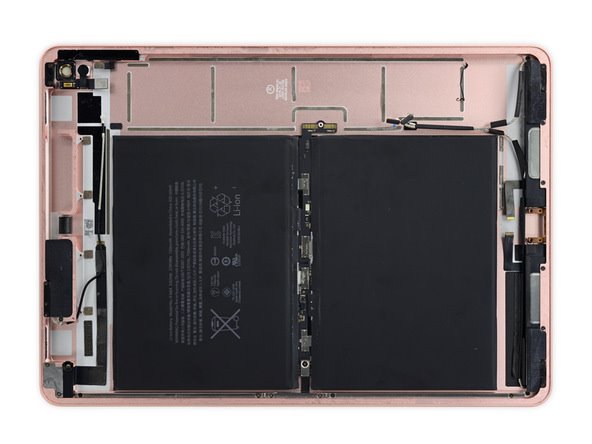

2. Refurbished LCD replacement screen

The majority of damaged screens are glass-only broken screens, while the LCD display and digitizer still work. To refurbish these screens with brand new glass replacements can make them back to life and market again.

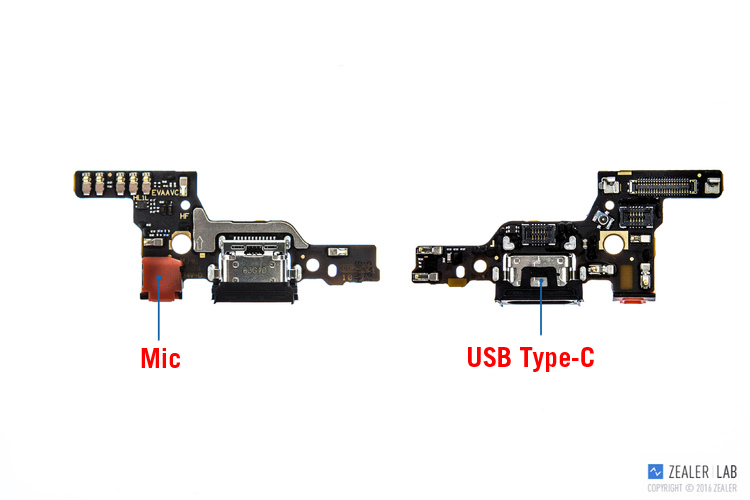

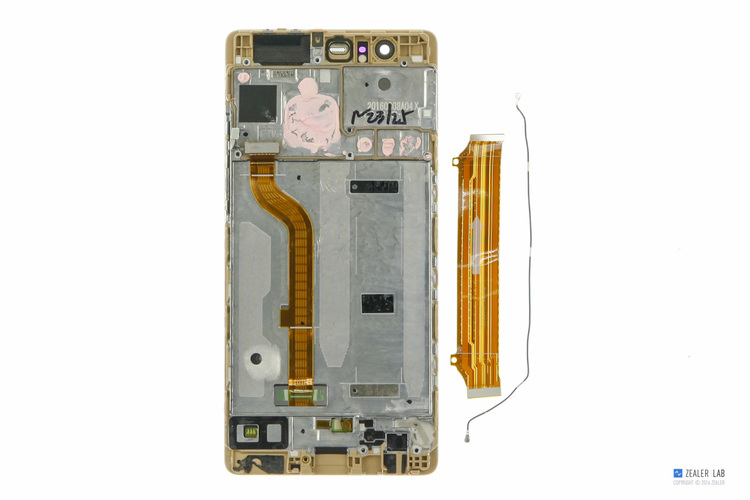

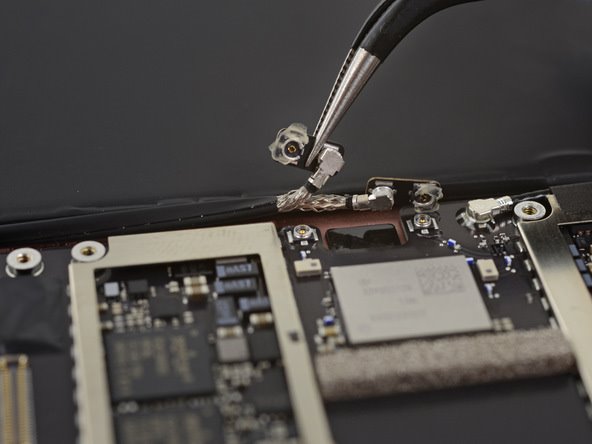

3. Flex-assembled LCD replacement screen

Apart from the original LCD assembly replacements, some original spare or defective LCD displays are seeping into the market. And some small third-party manufacturers will purchase and turn them into final replacements by assembling with new glass lens, adhesives, digitizer frames, backlight films, LCD ICs etc.

4.OEM-Compliant LCD replacement screen

The OEM-complaint replacements showed up because of the imbalance between huge demands for replacements and few original stock in availability. Comparing with the original screens, OEM-complaint ones work but still need to be improved regarding the display effect and working stability.

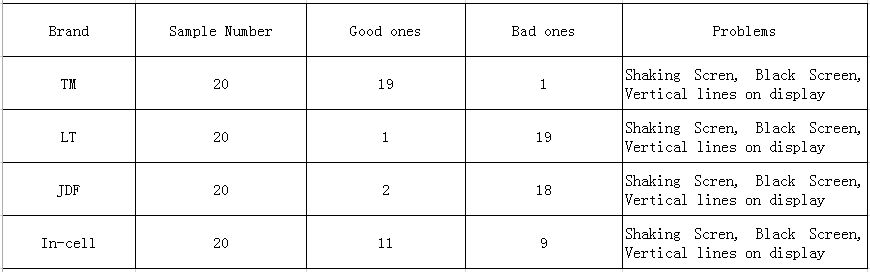

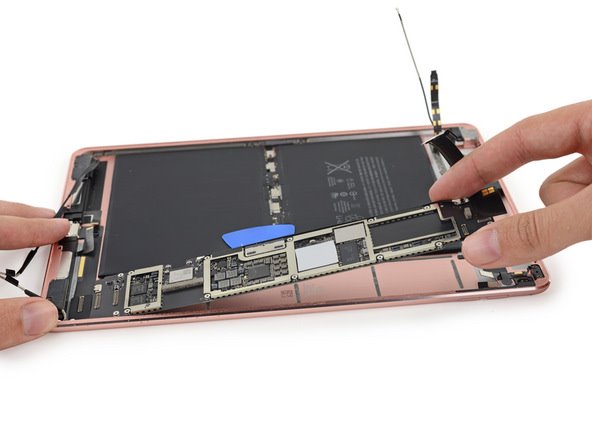

Judge from the market demand, the original, refurbished and flex-assembled LCD screen, which uses the original LCD, are the most needed replacement in the market. However, since last June, the original LCDs are more and more difficult to be obtained due to the strong control of original factories for the spare inventories and defective LCDs, which makes the original LCD price rises drastically and leads the repair shops and screen replacement suppliers into a dilemma. In order to meet the demands of these repair shops, the parts suppliers customized and ordered the LCDs from the Chinese factories, and assembled these China made LCD screens by third party manufacturers. Subject to cost competition, the repair shops have no choice but to purchase the China made LCD screen replacements instead.

In the long run, the price of original LCD screen will not decrease so much due to shortage of supply.

So what effects will it truly bring to repair shops when iPhone features the OLED screen?

The OLED technologies, are basically monopolized by LG and Samsung while the LCD production technology are already quite mature in China (both in high, medium and low-level). Unfortunately the Chinese LCD screen manufacturers for the time being has no technical strength to produce the small size OLED screen replacements in bulk and high standards (TM and JDF OLED product line are being under construction and pre-production, however, considering the product standard compared to iPhone, there is still a large gap). Besides, the 3D touch function of iPhone LCD screen assembly increases the technical difficulty of production. Had to say that the China made OLED screen replacements can’t meet the demands of the market in short term.

As for the third party repair shops, the refurbished LCD screen which comes from the glass-only broken LCD screen of customers, will be the major source of screen, and today is not the worst day for third party repair shops.