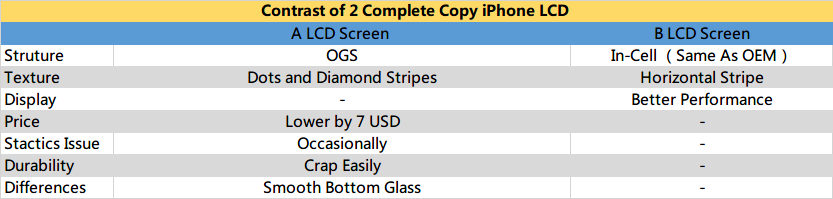

In cellphone repair community, many repair shop owners have to accept the high price of iPhone LCDs due to shortage and other reasons. However, as the invisible hand in the market try to adjust the situation, some complete-copy iPhone LCD assemblies come out to balance the supply and demand. Below is what we want to tell you guys about the complete-copy LCD screen, including features and price.

Insiders said, there are two main Chinese manufacturers producing the copy parts. For some reason, below we will call them A factory and B factory, same with A LCD and B LCD. Different copy iPhone LCD parts match with different prices and function stability. The root of the difference is the LCD manufacturing technology.

*A: LT Manufacturer B: TM Manufacturer

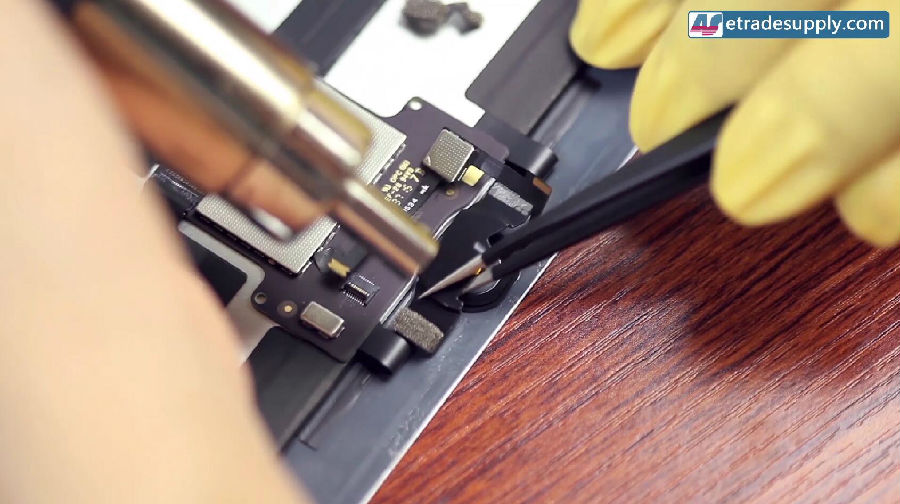

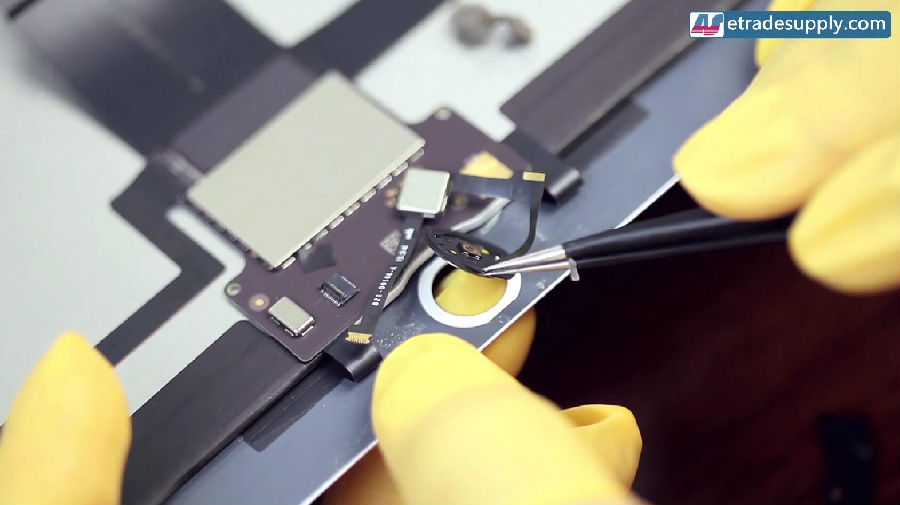

Structure

A manufacturer uses the OGS technology to make the copy iPhone LCD. Since this technology is out of date, the A LCD has some obvious features people can make out by eyes. As we mentioned in

the previous blog, the A LCD parts has built the digitizer touch screen on the glass lens. However, to make sure the LCD screen assembly as thin as the OEM LCD screen assembly and no installation issue, the glass lens was made as thin as

0.38mm, almost a protective film.

Texture

With digitizer built on the thin glass lens, you can see the digitizer texture on the screen, which is in diamond shape. Meanwhile the B LCD screen also has horizontal stripe on it but not clearly.

However, since the glass lens is so thin and the digitizer is built in, once the LCD screen breaks, the whole LCD screen assembly won't work anymore.

Display

Compared with OEM LCD screen assembly, the 2 complete-copy LCD screen assemblies both have some color shading in specific color display. Take gray display for example:

Price

With the different technologies, the A LCD which use OGS has lower price. Compared with B copy LCD, the price is lower by 7 dollars. But since the iPhone LCDs are in great demand, the price of A copy LCD parts are expected to keep rising though. According to the latest pricelist, the copy iPhone LCDs' prices aren't cheap enough to stay competitive.

Static Issue

Since the glass lens of A copy LCD screen is as thin as 0.38mm and the digitizer is assembled under the glass lens, the digitizer is very easy to be affected by the statics from finger, which will lead to the failure of the digitizer. Only to restart the device will help to wake the digitizer touch screen. While the B factory roll out the B copy LCD after A factory, they have avoid the issue by using the latest In-Cell technology.

Durability

Generally speaking, even though our smartphone breaks, it is still working in most times. The digitizer touch screen is not damaged when phone drops. However, with digitizer built under the extremely thin glass lens, when the phone with A copy LCD screen drops or breaks, the whole LCD screen assembly stop working. You can’t input anymore for the failure digitizer touch screen. Meanwhile, with another structure, the B copy LCD screen assembly will survive under this circumstance.

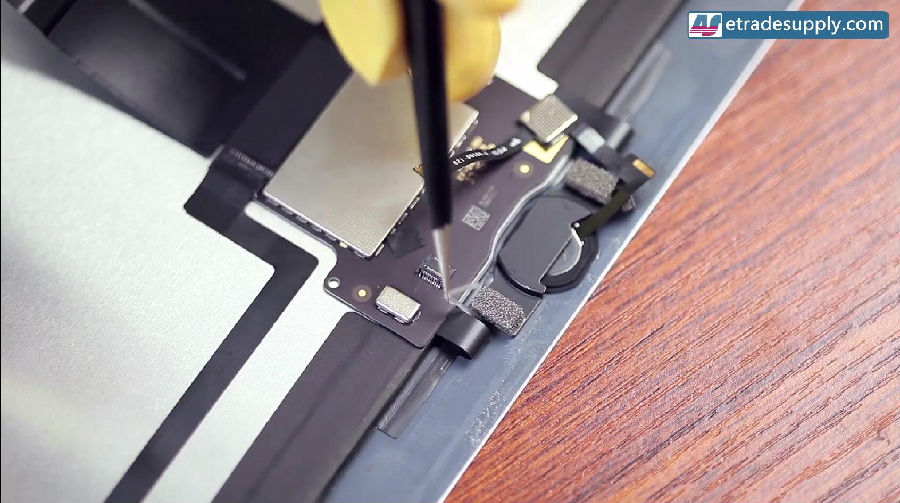

Tips for Telling the Copy LCDs without Teardown

As we said, you can find out the copy parts from OEM by the textures for no textures on OEM screens. Furthermore, there are some tips shared with our community to tell the different copy LCDs.

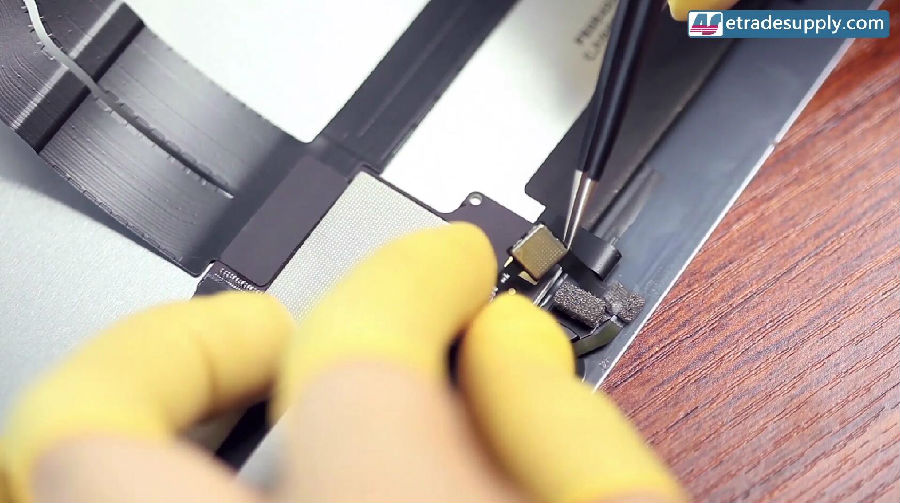

First of all, the structure of the LCD screens. The glass lens on A copy LCD is much thinner than B copy LCD. You guys can check it out through home button openning.

Secondly, the glass surface on the top of back of the LCD screen. The top glass part on A copy LCD is very smooth while the OEM LCD and B copy LCD have a uneven appearance, The matt surface is used to provide better grip for the glue when applying camera bracket. OEM and B LCDs make sure the camera braket will be held tightly.

Thirdly, the glass surface on the bottom of back of the LCD screen around the home button. The Copy parts both have smooth surface on the bottom glass. For the A copy LCD screen, it use glass to increase the thickness to make sure no gap during installation.

As far as we know, another Chinese manufacturer is going to release a new complete-copy iPhone LCD screen assemly. The new copy LCD have fix the previous generations' copy iPhone LCDs' issues, according to the insiders in JDF, the third main copy iPhone LCD screen manufacturer. At present, we have gotten the copy iPhone LCD samples and will show you guys the testing result ASAP. Don't miss our latest breaking market info! Please follow ETrade Supply on

Facebook and

Twitter. Any questions, please feel free to contact us at service@etradesupply.com or just comment below.