Since 2013, more and more cellphone manufacturers started using aluminum as the body panel material like: HTC One and the following HTC One M8, HTC One M9 as well as the latest HTC A9 rear housing. Not to be outdone, Apple has been used aluminum on the latest iPhone rear housings such as iPhone 6S, 6S Plus. What are the specialties of an aluminum housing? How does it made from a metal?

Well, there’re 3 kinds of techniques to forge aluminum housing: all CNC, die casting and CNC + die casting. Most cellphone manufacturers adopt die casting as the main technique as it requires lower cost, less time and fewer raw material. How does it work? Here’s the working procedure for reference:

1. Material Selection

Actually, the above-mentioned cellphone back panels are made of aluminum alloy not pure aluminum as it features differently according to the different ingredients, while the pure aluminum is not qualified in neither strength nor hardness. For example, the iPhone 6 rear housing is made of 6000-series aluminum alloys, it’s easily to bend but has better ductility. However, the iPhone 6S rear housing is not that easy to bend but more easily to get cracked as it’s made of 7000-series aluminum alloys.

2. Melting Process

The die casting technique is melting the selected aluminum into liquid instead of cutting it directly.

3. Injection Molding Process

After the aluminum bulk being melted into liquid, it flows down from the arachnoid slots. Then it’s stamped with incredible pressure to become a housing panel rudiment.

It sounds easy, isn't it? However, emergency could happen at any time, you have to make sure no sand bores in this process as they will bring about pits in the cutting process coming after. Techniques and molds are repeatedly modified to prevent it happen from the beginning and that’s why lots of raw materials are wasted during these improvements.

4. Spray Painting Process

After being die casted (process 1~3), these prototypical housings such as iPhone back housings will be anodized to make them look more metallic-like. While some others will be spray painted with a soft and warm coating.

The basic housing shape comes out after cutting down the extra parts and removing the burrs. As you can see on the above picture, there’s a hole in each housing, which is for plastic ejection so as to reinforce the metal panel body. Like the plastic print on the white antenna stripes of iPhone 6 rear housing.

Now it’s time to spray paint after plastic ejection. There’s a clear diving line between the metal and plastic, if it’s done with less skillful spray painting, the line will still obviously to be seen even after final painting.

Take below housing replacement as an example, 16 spray-heads dividing into 8 sets to ensure the spray-painting is all-around and evenly.

5. Stove Painting Process

Here in below is a picture showing the aluminum back panels being stoved after spray painting. The painting process ends up with 5 times of spray painting, 5 times of stove painting and 2 times of polish (one is for paint undercoating and the other for adding pearl powders or aluminite powders).

6. Diamond Cutting Process

Before diamond cutting, the back housings will be craved holes for rear facing cameras, volume buttons, loudspeaker etc.

Then the aluminum panels will be cut by a machine with a diamond as the cutter tool. Like stove painting, diamond cutting should be proceeded at least twice to make the housings look shiny.

To make sure the cutting width and angles in the required specification, a laser aligning tool will run along the traces to be cut and the relevant information will be sent to the machine, then the diamond cutting starts.

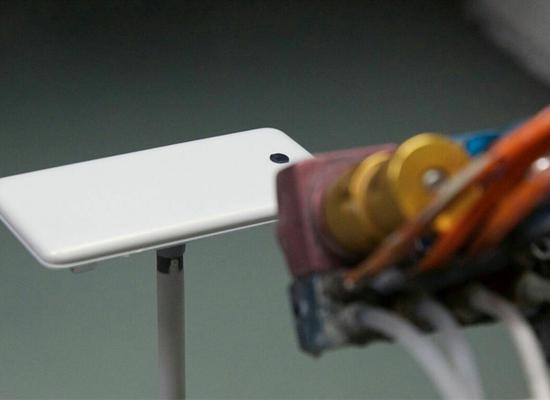

Here is a close-up picture for the diamond cutter.