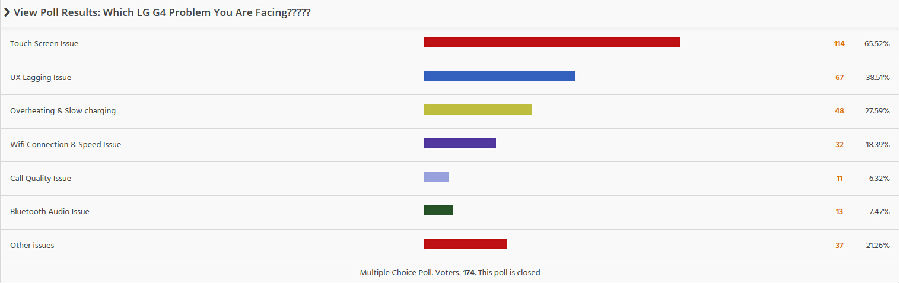

Different Types of iPhone 6 LCD Screen Assemblies in Market

The

iPhone 6's LCD Screen assembly is the latest iPhone LCD in market. Since its release roughly 1 year ago a lot of original iPhone 6 LCDs were widely available in the market, but iPhone 6 LCD screen assemblies in the market can be divided into 3 groups by their materials:

1. Apparently,the first type is the wholly original iPhone 6 LCD screen and digitizer assembly.

2. The second type is the iPhone 6 LCD screen assembly assembled with different materials both from OEM producers and 3rd party sources.

3. The last type is made with refurbished parts, but this kind of iPhone 6 LCD screen assembly is hard to find, as the iPhone 6 has not been on the market for long enough yet.

The LCD screen is the most important part in an iPhone 6 LCD screen and digitizer assembly, and can't be copied or reproduced by 3

rd party factories yet. So for now all of the iPhone 6 LCD screen assemblies in market have original LCDs, but to make a working LCD screen assembly for the iPhone 6 a single LCD screen is not enough. Depending on the rest of the materials, the assembled flex parts can be several different types. The types of

assembled flex iPhone 6 LCD screen assemblies below are easy to find in market:

1. All of the materials are original produced but assembled by 3rd party factories.

2. Original LCD screen, flex ribbon and backlight assembled with a 3rd party produced cover lens and other parts.

3. Original LCD screen and flex ribbon assembled with the rest of the materials produced in 3rd party factories.

4. Only the LCD screen is original while the rest are all copied parts.

Different products have different quality, the same with their price tag. As for the quality and stability. Surely, the original parts excel over others, and the refurbished LCD screen assemblies work better than assembled flex LCD Screen assemblies. Here is why:

1. Adhesive. When LCD screens are assembled with the flex cable, special adhesive is used to make sure that the two parts are connected firmly, and the signals transferring between flex cable and LCD won’t have issues. The technology in 3rd party parts can’t promise everything will work perfect, and they also don't use a special adhesive but a normal adhesive.

2. IC on the flex cable. In OEM factories, workers will clean the IC and make sure they are clean when they load a metal cover on the IC, which help keep the IC working stably. 3rd party factories skip this step during the production process.

3. Connectors. The contacts on the connectors need to be soldered neatly and firmly, otherwise after the connectors are disconnected and reconnected to the motherboard a few times the contacts become loose and the LCD may become defective. The LCD screen is unable to show the correct images as the signal is disrupted by the connector not being connected well. This results in vertical stripes on the screen or even worse issues.

4. Flex cable. The OEM factories need to produce softer and more flexible digitizer flex cables to make sure that they will not break during installation and after being folded many times, while 3rd party factories’ flex cables tend to become defective after being handling several times. The flex cables produced by 3rdparty factories are harder. Experienced technicians or sourcing agents can tell the difference just by feeling the flex cable.

5.

Frame. 3

rd party factory produced iPhone 6 frames are easier to separate from the LCD screen assembly. As we have written

a blog about the issue, the reason and the analysis behind the issue is the adhesive. Easier to come off and a thicker iPhone 6 frame will result in issues for the iPhone 6 LCD screen assembly.

How to Tell Original iPhone 6 LCD Screen Assemblies from Fakes

In general, the different iPhone 6 LCD screen assemblies in the market can be differentiated by materials and production techniques. We show you how to distinguish whether the parts are real or counterfeit.

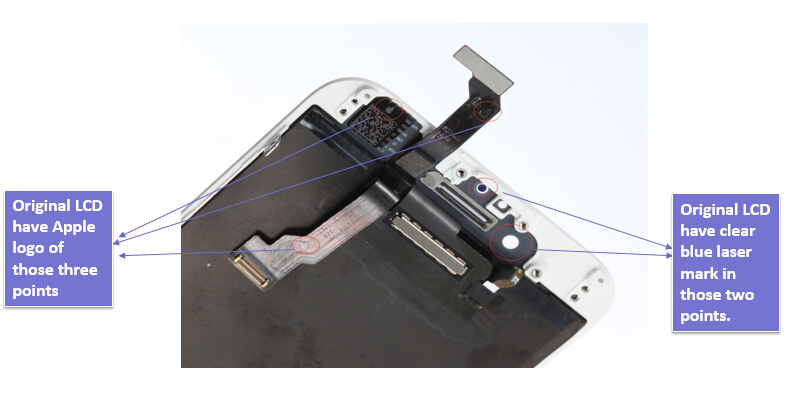

Laser mark. There is a laser mark on the front facing camera's retaining bracket and proximity sensor retaining bracket. If the laser mark is present then you will be able to see a blue layer of film reflected in the light on the covers.

2. Smoother and shinier frame. To tell the difference by the frame, you can look at and feel the edges of the frame.

Real OEM iPhone 6 LCD Screen Assemblies have a smoother and shinier frame while copy parts will be rough and tarnished. It’s not easy to accurately describe the difference between OEM and a copy part. The only way to figure it out is to touch and feel the parts, but essentially a real OEM part will have smooth brackets on the frame with no small metal shavings coming off them. Moreover, the texture of the frame bottom sometimes can also tell you the difference by contrast.

3. Adhesive overflow marks. One more thing you can look for is dried excess adhesive. After many tests, an OEM producer can precisely control how much of the adhesive is applied to the frame, while 3rdparty factories are unable to. So you can look to the edges of the frame to see tale tell signs of excess adhesive showing you whether or not the part is OEM or a copy.

4.

Smoother edges on the lens cover. Real

OEM LCD screens are darker or shiner than fake copy ones. Compared with the original part, iPhone 6 LCD screen copies tend to have a gray tint to them. As for the glass lenses, the rim and the edges of the OEM parts feel much smoother to the touch around the four corners. Reclaimed or copy parts may have kind of a rough trim on the rim and the edges.

5. Apple's logo. Check to see if there is an Apple logo printed on the flex cables or not. Generally speaking, a fake iPhone 6 LCD Assembly won't print Apple logos on the flex cables to reduce cost. An OEM part must have Apple's logo on it, however, an Apple logo printed on the flex cable won't guarantee you have an OEM part. If there are Apple logos printed on the flex cable, you need to check how clear they are to find spot the difference.

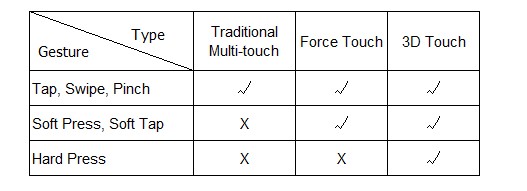

6. Softer and more flexible digitizer flex cables. OEM factories need to produce softer and more flexible digitizer flex cables to make sure that they will not break during installation or after being folded many times. These softer flex cables have a much higher production cost then standard harder flex cables. Keep in mind that only the digitizer's flex should be softer, while the LCD's flex will be harder even on the OEM part.

All of the above info is about what kinds of

iPhone 6 LCD screen assemblies are available in market and tips for how to distinguish the parts. But we still need to know what kind of quality they are. Furthermore, even for OEM iPhone 6 LCD screen assemblies, there are different quality grades among them, the same with assembled flex parts and refurbished LCD screen assemblies.

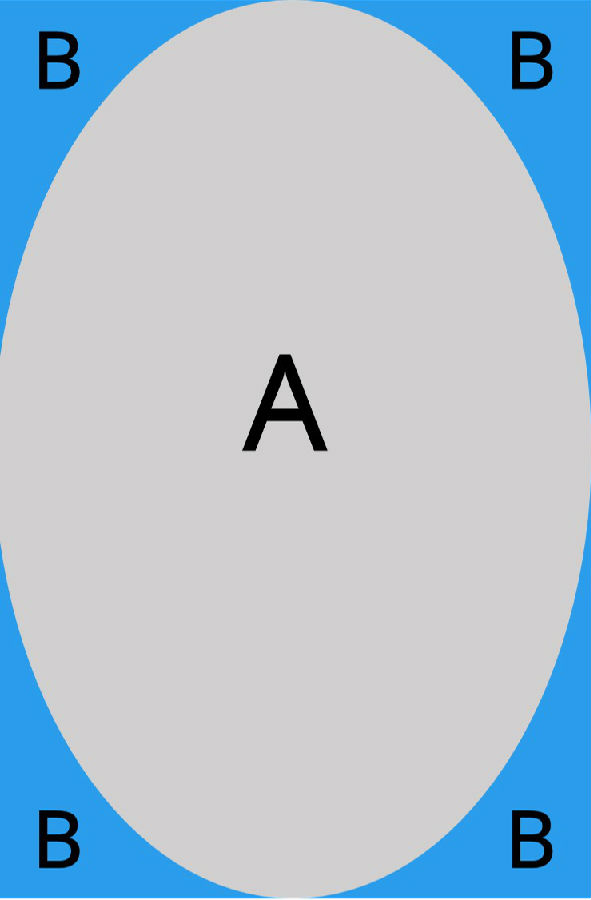

In general, depending on appearance and function test, the quality grades are divided into 3 groups: A-grade, B-grade and C-grade. Appearance inspections include whether there are scratches or not, how much they are, and if there are any cracks or not. Functionality tests need to check for dead pixels, stuck pixels, white screen, color screen or digitizer malfunction etc.

At ETrade Supply's store, we make sure A-grade parts are absolutely in great condition,while B-grade items have tiny cosmetic imperctions as we have described in the product description. C-grade products are not available at ETrade Supply's store. We believe that we should and always keep providing best parts in market. That's our value.

How ETS Test Their iPhone 6 LCD Screen Assemblies

There are 2 types of iPhone 6 LCD screen assembly in the ETrade Supply webstore, including

A-grade and

B-grade. A-grade items are 100% OEM produced and manufactured while B-grade items may be produced by 3rd party factories or OEM producers with small cosmetic imperfections, but they all function as well as A-grade parts. You can see the iPhone 6 LCD screen and digitizer assembly's quality test standards below:

1. Appearance inspection: check if there are any flaws, impurities, scratches and/or cracks.

2. Function test:

a) Check for bright spots, dead pixel stains, light leakage or a line on the screen. Check if the screen has issues such as a single color screen or a white screen.

b) Test the digitizer for dead spots and other malfunctions.

|

iPhone 6 LCD Screen Assembly Test Grades

|

Grade

|

Flaw

|

Scratch

|

A+

|

Flawless in A area while at most 1 point in the B area, diameter between 0.01mm and 0.15mm

|

1 scratch at most, under 0.5mm in B area

|

A

|

1 point in A area and 1 point in the B area at most, diameter between 0.01mm and 0.15mm.

|

1 scratch under 0.5mm in B area

|

A-

|

2 points in A area at most, diameter between 0.01mm and 0.15mm and at most 1 point in the B area, diameter between 0.01mm and 0.15mm

|

1 scratch under 0.5mm in A area;2 Scratches Under 0.5mm in B area

|

B+

|

At most 1 point on the screen, diameter between 0.15mm and 0.3mm

|

1 scratch on the screen between 0.5mm and 2mm

|

B

|

At most 2 points on the screen, diameter between 0.15mm and 0.3mm

|

1 scratch between 0.5mm and 2mm in A area;1 scratch between 0.5mm and 2mm in B area

|

B-

|

At most 2 points on the screen, diameter between 0.15mm and 0.3mm

|

3 scratches between 0.5mm and 2mm on the screen

|

As you can see, the quality tests for iPhone 6 LCD screen assemblies at ETradeSupply are stricter than other suppliers in the market. Even when we communicate with OEM suppliers, we also stick to the standards to select only high quality parts. Before the parts are registered in our system, they are strictly tested, such as exert excess force on the frame to see whether it will come off or not to make sure it will last when installed on a customer's device. We spare no efforts to make sure our A-grade parts reach these standards:

1. Appearance: No flaws, no scratches.

2. Frame: Pass through high temperature and low temperature tests.

3. Function: No stains, No stripes.

4. Shipping: Secondary tests before being shipped.

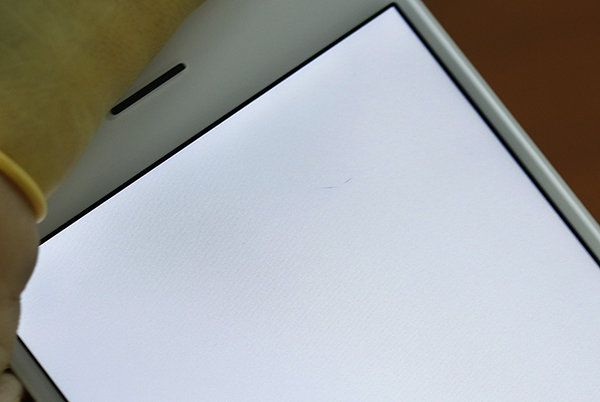

Show you some B-grade and C-grade parts in market examples below:

B-Grade

B-Grade

B-Grade

C-Grade

C-Grade

C-Grade

Tips for Installation

According to our customers' feedback and our engineer's suggestions, we hope that everyone who replaces their iPhone 6 LCD screen assembly by themselves will pay attention to these 2 tips to make sure everything works.

1. Static. From our experience, after failing to install an LCD assembly the first time, when you try to install it by connecting the connector to the motherboard the second time static will be generated and it will damage the IC on the flex cable or connector rendering the assembly defective. Thus, when replacing the LCD screen assembly, you should always remember to have an anti-static wristband on your hand or other static prevention measures in place.

2. Flex ribbon. As we have stated above, flex cables are very easily damaged. So handle them very gently! Avoid bending the flex ribbon too much, and pay attention to how the flex is lightly folded to fit into the case.

Purchasing Recommendations:

-If you prefer high quality products with no cosmetic imperfections, we recommend you buy

A stock products.

-If you prefer higher quality to perfect appearance we recommend you buy

B stock products.

More information, please check

our website or like

our Facebook page, and you can also contact us at service@etradesupply.com for any questions. We are glad to hear from you and will reply ASAP.